Категории

Последний блог

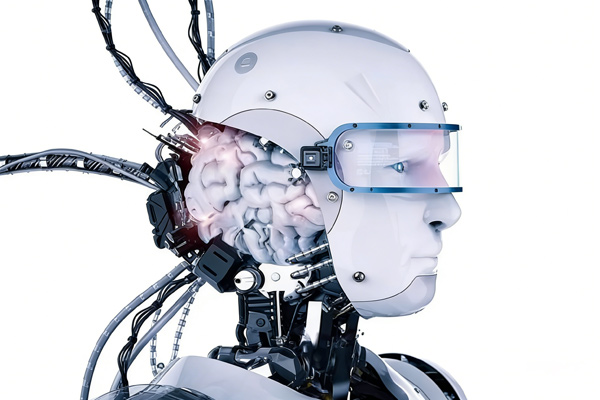

В робототехнических системах, автоматизированном оборудовании и интеллектуальных машинах защита кабелей — это не второстепенный аспект.

Это напрямую влияет на надежность системы, затраты на техническое обслуживание и долгосрочную стабильность работы.

Среди наиболее часто используемых решений — роботизированные цепные захваты и самозавязывающаяся плетеная рукавная лента Их часто сравнивают, но они предназначены для совершенно разных задач.

В этой статье объясняется, когда следует использовать кабельную цепь, когда — самонаматывающуюся муфту, и почему во многих системах на самом деле необходимы оба варианта.

1. Роботизированная цепочка для перетаскивания: разработана для структурированных, повторяющихся движений.

Тросовая цепь (энергетическая цепь) робота предназначена для направления кабелей, шлангов и трубок по заданной траектории движения.

Типичные характеристики

Наиболее подходящие приложения

Ограничения для проводов датчиков

Несмотря на свою прочность, цепь торможения имеет четкие границы:

Для тонких проводов датчиков кабельные цепи могут быть слишком жесткими, особенно вблизи разъемов и выходных отверстий.

2. Самозатягивающаяся плетеная защитная оболочка: гибкая защита для реальных условий эксплуатации.

Самозатягивающаяся плетеная оплетка предназначена для локальной защиты, а не для структурной поддержки.

Основные преимущества

1. Открытая, самозакрывающаяся конструкция.

2. Бережно воздействует на тонкие провода датчиков.

3. Отличная износостойкость

3. Почему одних только цепей недостаточно.

В реальных роботизированных системах большинство отказов кабелей происходит не внутри тяговой цепи.

Они происходят в:

Именно в этих зонах самозатягивающаяся защитная оболочка показывает наилучшие результаты.

4. Практическое руководство по выбору: цепная передача против самонаматывающейся муфты.

|

Область применения |

Рекомендуемое решение |

|

Длинные, повторяющиеся движения |

Роботизированная цепная перетаскивание |

|

Тонкие сенсорные провода |

Самозатягивающаяся рукавная лента |

|

Защита выхода разъема |

Самозатягивающаяся рукавная лента |

|

Системы, требующие частого технического обслуживания |

Самозатягивающаяся рукавная лента |

|

Высокая плотность кабелей внутри цепи |

Совместное использование |

5. Типичная длина самообмоточных рукавов в роботах.

Вместо того чтобы полностью закрывать весь кабельный трассу, инженеры обычно защищают только критически важные участки.

|

Расположение |

Типичная длина |

|

Датчик к неподвижной точке |

200–500 мм |

|

Соединительная или поворотная зона |

300–800 мм |

|

Выход из шкафа управления |

300–1000 мм |

Этот целенаправленный подход к защите:

6. Лучшая практика: комбинируйте, а не заменяйте.

Вопрос не в том, "цепь для протяжки кабеля или самозатягивающаяся муфта".

Профессиональный ответ таков:

Для управления движением используйте цепи, а для защиты в местах поломок — самозатягивающиеся муфты.

Эта комбинация:

Эффективная защита кабелей робота заключается не в выборе самого надежного решения —

Речь идёт о выборе правильного решения для каждой части системы.

Для проводов датчиков и гибких сигнальных кабелей, Самозатягивающаяся плетеная оболочка обеспечивает защиту, не жертвуя при этом удобством использования.

Именно поэтому оно стало предпочтительным решением в следующих областях: